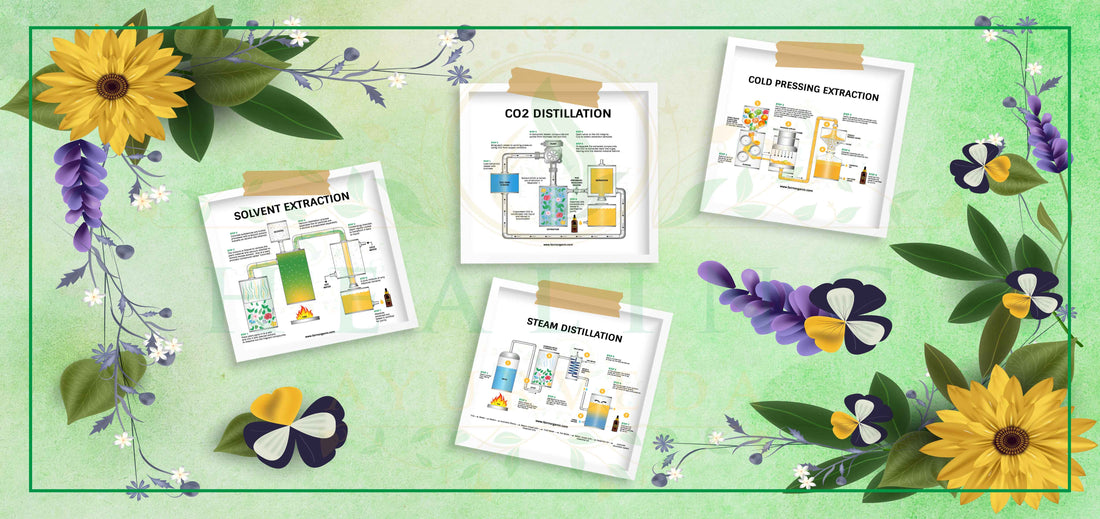

EXTRACTION METHODS

Share

Steam Distillation

Steam distillation is used mainly to distill oils through a single process from natural raw plant materials. Consisting of the flowers, leaves, wood, bark, roots, seeds, or peel, is put into an alembic (distillation apparatus) over water and when the water is heated the steam passes through the plant material, vaporizing the volatile compounds. The vapours processed through a coil, where they condense back to liquid and then collected in the receiving container.

The steam from the boiling water carries the vapor of the volatiles to a condenser after that the water and the volatiles are cooled and return to liquid or solid state. The none-volatile residue left in the boiling container. The re-condensed water is referred to as a hydrosol, hydrolat, herbal distillate, or plant water essence, can be used as a fragrant product. Essential oils dissolve in alcohol and in fixed oils/carrier oils but not in water.

CO2 Extraction

The carbon dioxide is moreover inactive and thus does not chemically interact with the substance that is being extricated, this basically need to oust the weight underneath which it is kept. Pressurized carbon dioxide gets fluid while staying in a vaporous state, which implies it is presently "supercritical." In this state, it is siphoned into a chamber loaded up with plants.

Since the fluid properties of the gas, CO2 capacities as a dissolvable on the common plants, extracting the oils and other substances such as colors and resin from the plants. The essential oil substance at that point breaks up into the fluid CO2. The CO2 is brought back to characteristic weight and dissipates back into its vaporous state, the oil pulled over is resulted as Essential Oils.

This procedure needs to happen in a shut chamber, for the excessively high-pressure weight for carbon dioxide is 200 airspace - that is multiple times the weight of typical air.

Cold Pressing Extraction

Cold pressing is a mechanical extraction process, also known as expression or mechanical separation. Plants and plant parts (such as the skins of natural products) are set in a spike-filled holder and gradually punctured.The essential oil and pigments run down into the device’s collection area.

Cold press machines moreover utilize centrifugal drive to assist separate the oil from the rest of the plant mash and fluid.The oil and juice that are produced still contain solids from the fruits, such as the peel, and must be centrifuged to filter the solids from the liquids. The puncturing and turning prepare discharges the essential oils, which are at then collected.

In certain plants, high levels of heat extraction could cause the fragile and little particles inside the oils to break down and debase, which can minimize the oil's well being benefits, cold pressing extraction method has been implemented in order to preserve the integrity and potency of the oils.

Solvent Extraction

Absolutes are produced by solvent extraction. Solvent extraction is especially used to extract concentrated oils from delicate flowers that are too delicate for steam distillation. (However, Solvent extraction is also used for other non-delicate items) When a solvent such as Hexane or Supercritical Carbon Dioxide is used to extract the oils from flowers which contents a small quantity of evaporation oil to go through an extraction, but their chemical components are too fragile and effortlessly denatured by the high heat process used for steam distillation. Absolutes dissolve in alcohol and fixed oils but not in water.

Mostly Hexane or Supercritical Carbon Dioxide is used while Solvent Extraction process, these extracts are a mix of of essential oil, waxes, resins, and other lipophilic (oil-soluble) plant materials. The solvent is then evaporated off leaving a mixture of waxes and oil. These extracts are called as concretes. High fragrant, concretes contain highly fragrant and concentrated substance is called Absolute.

Regularly, another solvent, such as ethyl liquor, is utilized to extricate the fragrant oil from the concrete. The concrete solution chilled to −18 °C (0 °F) for more than 48 hours which accelerate out the waxes and lipids. These accelerates are then filtered out and the ethanol is removed from the remaining solution by evaporation, vacuum purge, or both, leaving behind the absolutes.